Hi, community,

Welcome to the first entry of the Open Manufacturing series, where we will share every important development and manufacturing phase of our #IoTIntoTheWild new products. We’re currently manufacturing our SenseCAP M2 Light Hotspot, so today let’s shed the light on it and dive into how we carried out the performance testing for this device. (

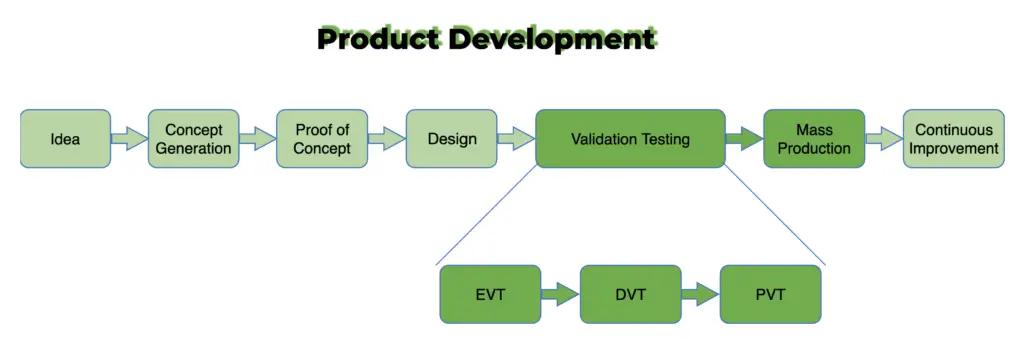

Performance testing is a type of testing that determines a product’s performance, such as durability, speed, scalability, handling, and stability. The testing process includes manual and mechanical endurance tests designed to reveal faults and ensure the product is fit for the market. Usually, the testing takes place in the DVT (Design Validation Test) phase in product development.

(Timeline of Product Development)

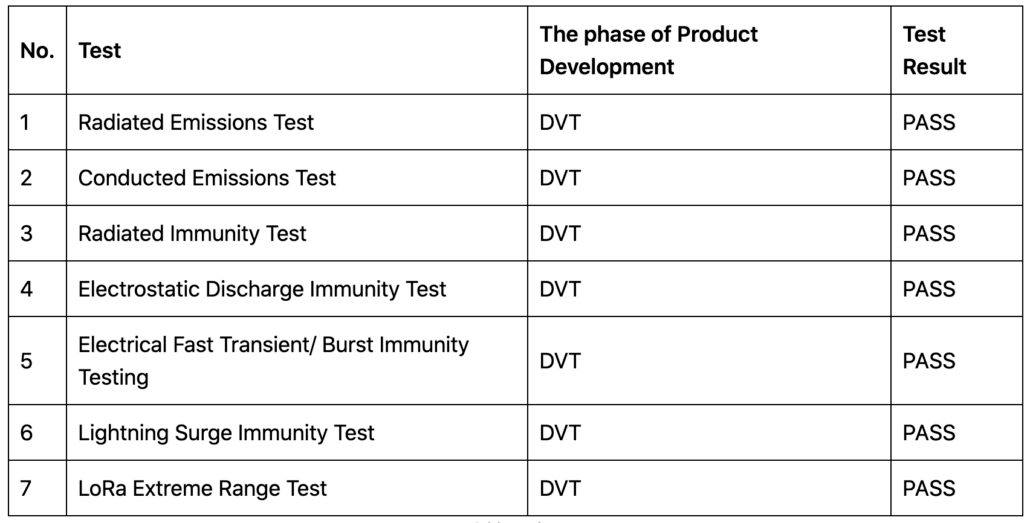

Since SenseCAP M2 is a LoRaWAN Helium hotspot connected to the Helium LongFi Network and provides miles of wireless network coverage and data transmission capacity for LoRa/LoRaWAN devices, the performance testing that we carried out for the device emphasized the tests for emissions and range apart from the tests for electronic & electrical appliances. Here is the list of the tests that our team focused on implementing (and all passed!!!

Have no clue about these tests? Let’s break them down and have a deep dive into the tests.

01 Radiated Emissions Test

Radiated Emissions Test usually involves measuring the electromagnetic field strength of the emissions that are unintentionally generated by the tested product. It’s by far the most common EMC (Electromagnetic Compatibility) test undertaken around the world. Emissions are inherent to the switching voltages and currents within any digital circuit, and the test is to ensure the radiated emissions of the SenseCAP M2 comply with the emissions limits in every major market in the world.

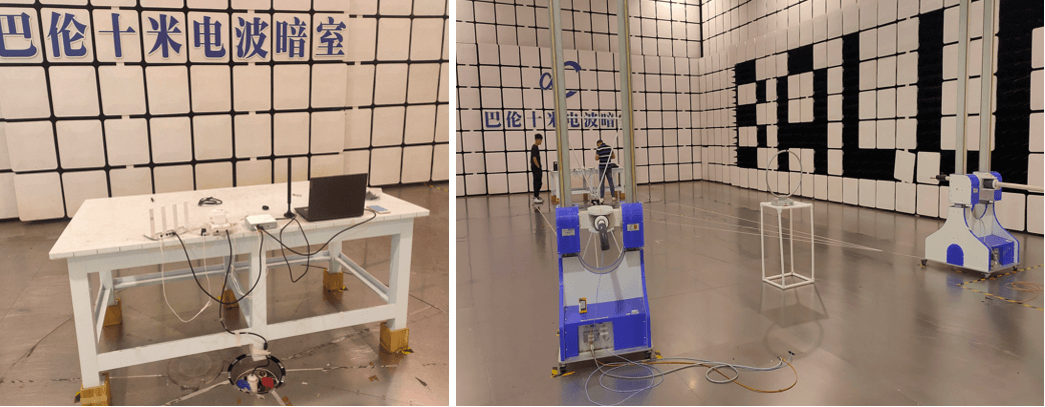

(The test site of the semi-anechoic chamber)

To get the most accurate measure, we sent the SenseCAP M2 to one of the FCC-listed EMC test sites owned by the Centre Testing International Co., Ltd(CTI). It’s tested in a semi-anechoic chamber, which is lined with RF absorber material so that reflected signals are kept to a minimum. In this way, the measurement antenna only receives a quantifiable signal contribution from SenseCAP M2, making the measurements quite accurate.

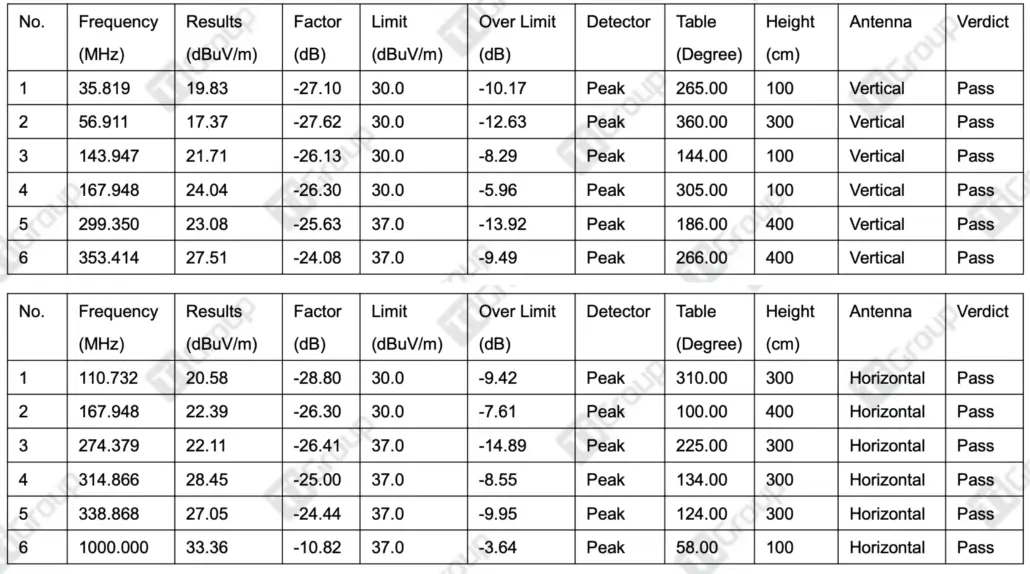

(The detailed test results)

02 Conducted Emissions Test

All the electronic devices including the SenseCAP M2 create electromagnetic energy among which a certain portion will be conducted onto the power supply cord. To ensure the local power supply remains relatively ‘clean’ and nearby devices (sensors or other gateways) won’t be affected by SenseCAP M2, we need to measure the conducted emissions (usually from 150 kHz – 30 MHz, and verify that they comply with specified limits.

When doing the test, SenseCAP sits on a table while the LISNs (Line Impedance Stabilization Network, a test tool) sit on the ground. The RF port of a LISN connects directly to a spectrum analyzer, where we can read the frequency ranges directly as above.

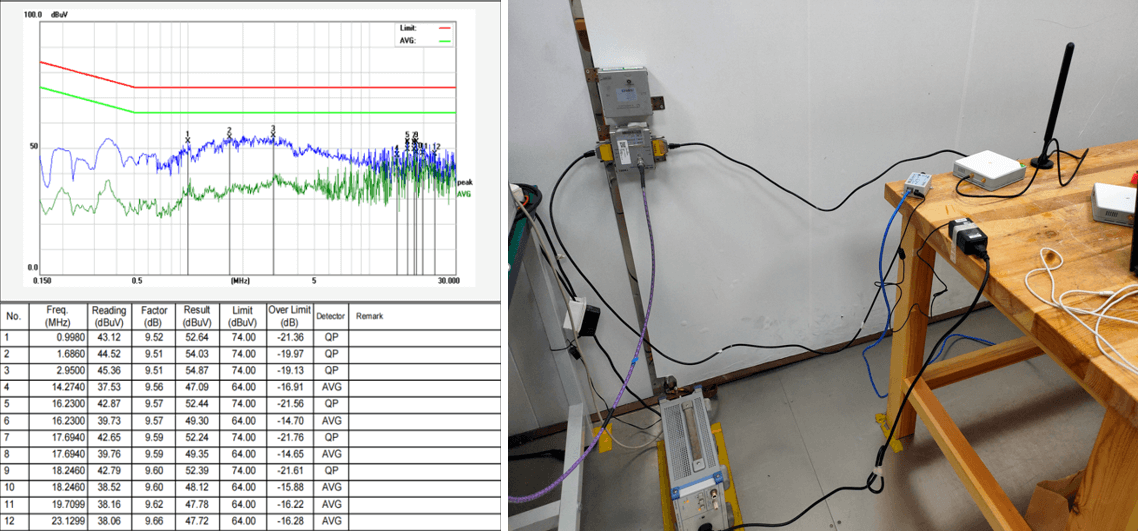

03 Radiated Immunity Test

In normal usage, SenseCAP M2 will encounter many different types of electric field disturbances such as electric field sources of a cellphone, motor, or other devices. And the Radiated Immunity Test is intended to see how well SenseCAP M2 will perform when it’s subjected to an electric field of a specified amplitude (measured in volts/meter) across a range of frequencies.

During this test, SenseCAP M2 is subjected to a uniform electric field in the Semi-anechoic chamber. CTI has calibrated the field at several points around the test area that SenseCAP sits within, shown as below.

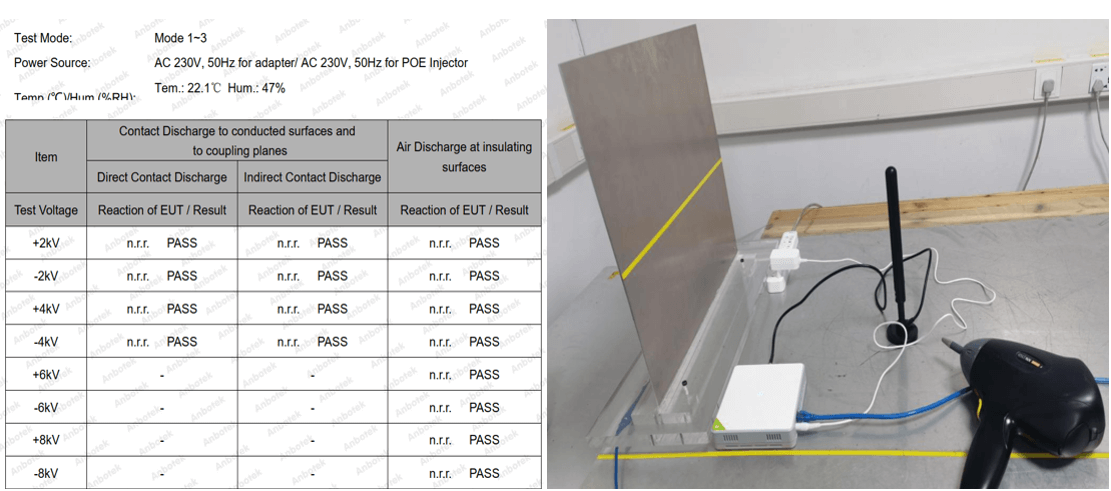

04 Electrostatic Discharge Immunity(ESD) Test

The purpose of this test is to simulate electrostatic discharge generated by human body intervention and evaluate the immunity of the product. To ensure this, the ESD testing of the SenseCAP M2 involves applying electrostatic discharges to any areas of its enclosure which is all accessible by human touch.

During the test, we applied two discharge tips to the tests: the air discharge tip and a contact discharge tip. The device has been tested in various voltages (low and high), and we’re glad to share that we passed all the contact discharge tip tests and air discharge tip tests.

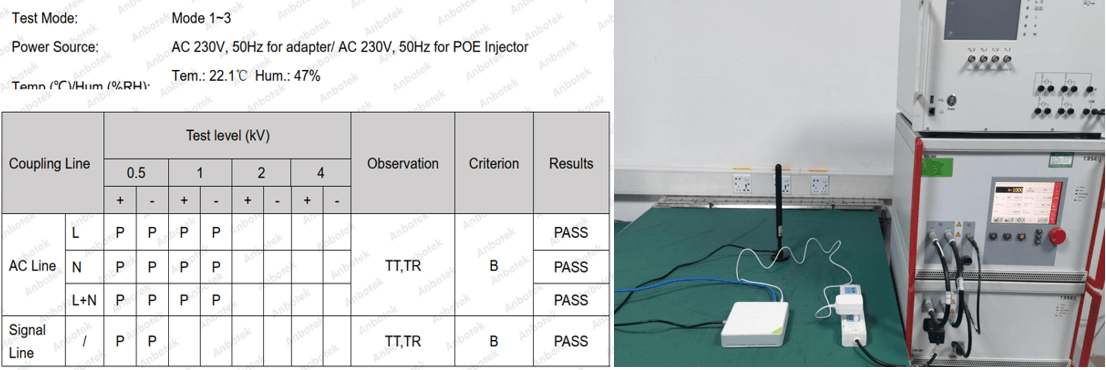

05 Electrical Fast Transient/ Burst Immunity Testing

The EFT immunity test is an attempt to simulate the switching of inductive loads in the real world. For this test, we applied the common EMC standard of IEC 61000-4-4 to measure SenseCAP M2’s capability to withstand the transient phenomenon of the electrical burst. Here are the results:

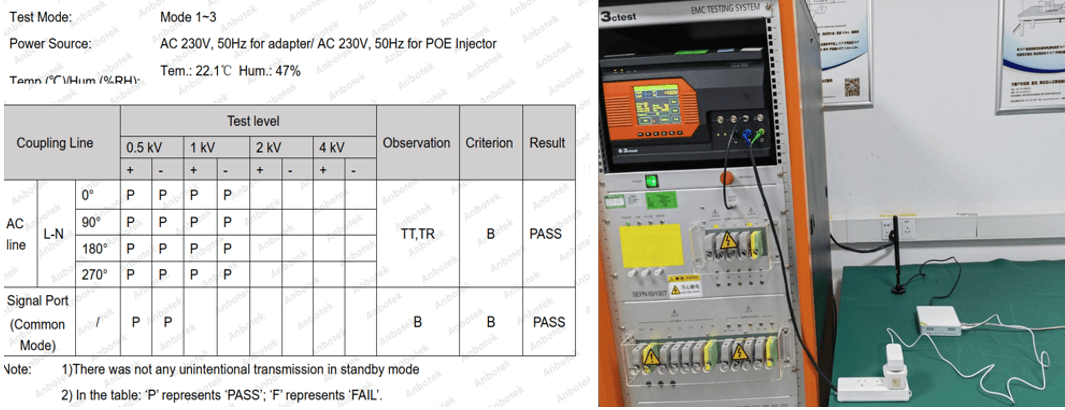

06 Lightning Surge Immunity Test

The surge immunity test is designed to simulate low-frequency power surges. The essential test equipment is called a surge generator, which generates the surge pulse for testing. During the test, the surge is both applied to the AC power input port and a signal port. And here are the test results.

07 LoRa Extreme Range Test

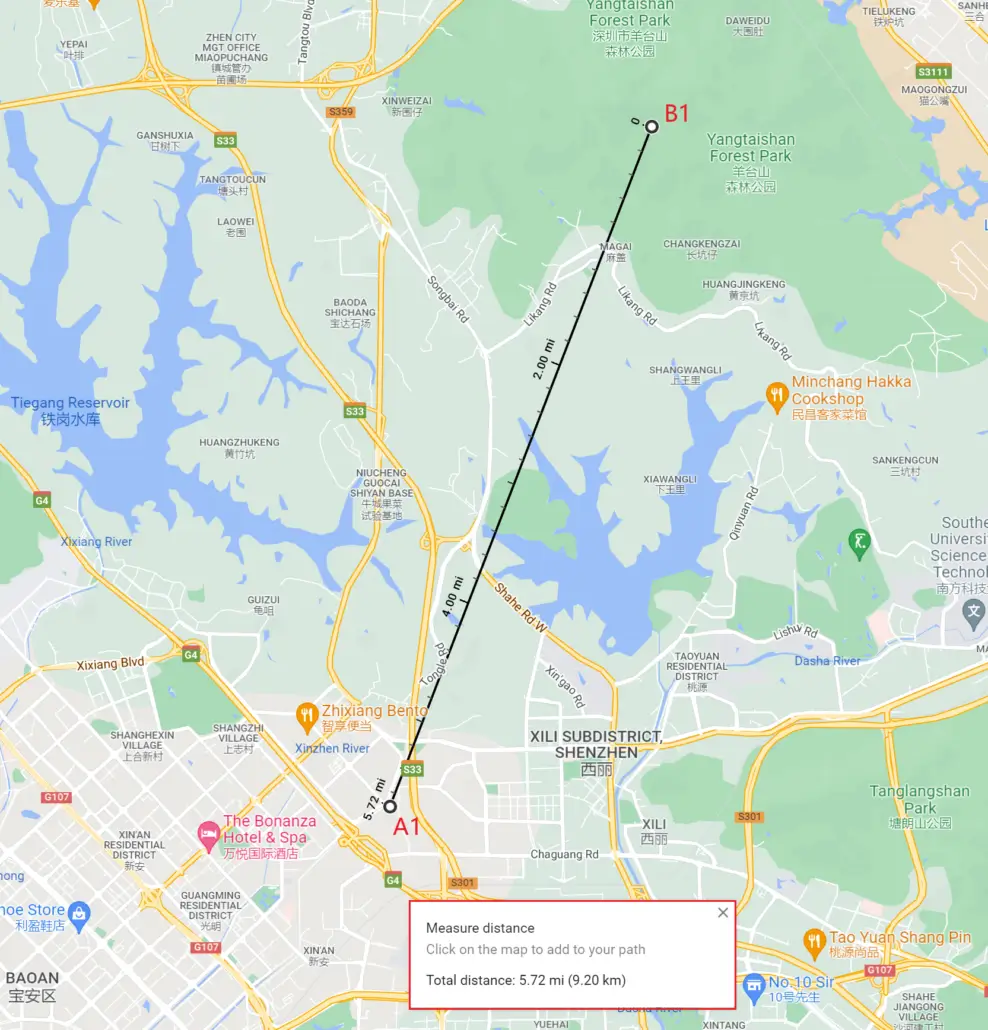

LoRa Extreme Range Test aims to know the performance of the LoRa module depending on great distances. To test the coverage of the LoRa module inside SenseCAP M2, we carried out both the Light of Sight test and the Non Light of Sight test (Urban Scene).

Testing Parameters

● Network Connection

● Delivery Rate

(The SenseCAP M2 Line of Sight (LOS) tests setup)

The Line of Sight (LOS) tests were taken between two different points next to the surrounding of Shenzhen(China). The emitter was set in point B1: of ‘Yangtaishan Forest Park’. The receiver was set in the point A1: of Seeed Office.

(The SenseCAP M2 Line of Sight (LOS) tests result)

The LOS coverage is 9.2km (with a 130cm fiberglass high-gain LoRa antenna). Since we were going to the top of the mountain while testing and reached the longest Line-of-Sight distance at 9.2km, hence the result was 9.2km. According to the evaluation, the actual data transmission distance can be up to 10km.

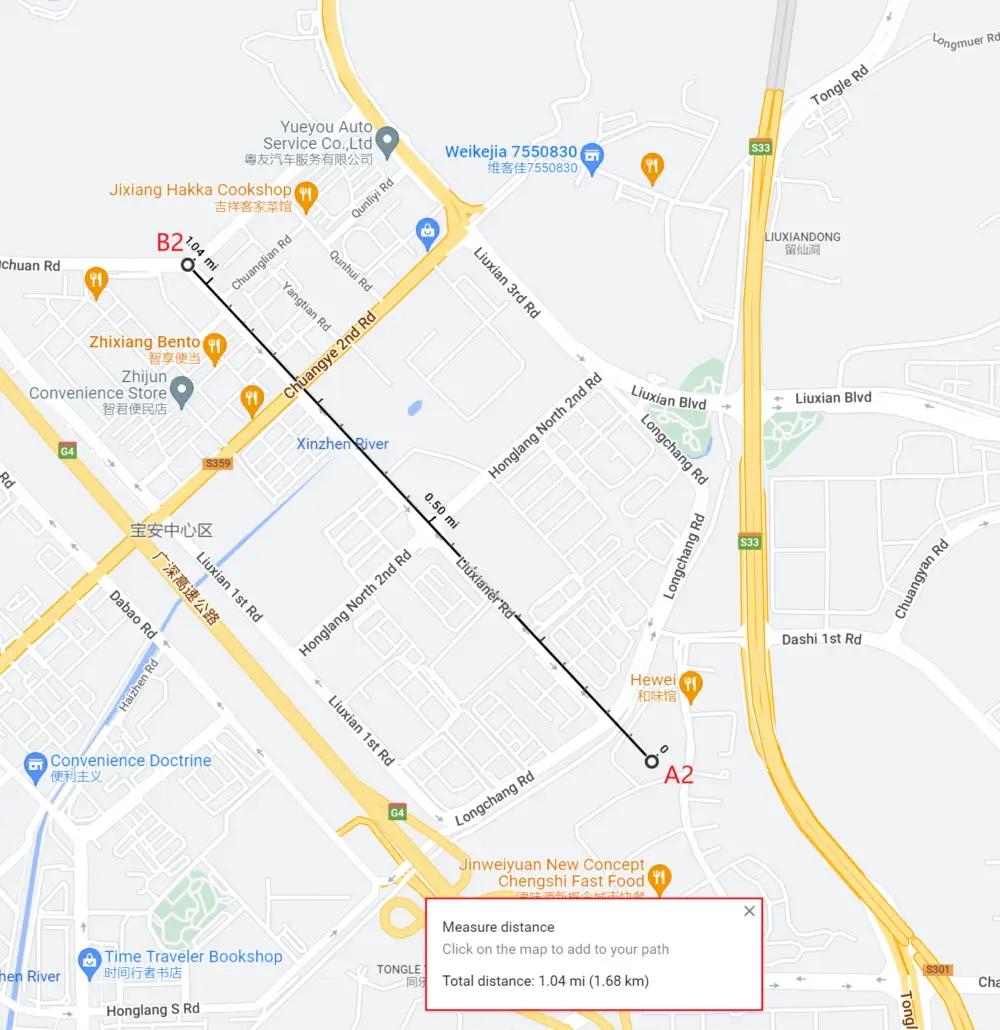

(The SenseCAP M2 Non-Line of Sight (NLOS) tests setup)

The Non-Line of Sight (NLOS) tests were taken between 2 points in the surrounding areas of our headquarters in Shenzhen (China). The receiver was the SenseCAP M2 Gateway (Location A2), installed on the rooftop garden of our office. The emitters are several SenseCAP S210X sensors (Location B2), which were set at several points around a street near Bao’an Environment Monitoring Mansion in Bao’an District.

(The SenseCAP M2 Non-Line of Sight (NLOS) tests result)

The NLOS coverage range is 1.68km with a stock LoRa antenna. We started from the Seeed office and walked along Liuxian 2nd Road while testing the products(We ran the same test two years ago). The longest distance with the expected delivery rate was at Location B2.

For more details about the LoRa Range Tests, you can click here to learn more details.

That’s all for today. Any feedback or any other details that you want to explore but we forget to include? Comment to let us know. Please stay tuned for our next entry, where we will talk about how we carried out the Reliability Test for the SenseCAP M2.

Until next time! 🙂

About #OpenManufacture

Why are we doing this? Manufacturing has long remained a challenge for developers to mass manufacture their projects at scale. So to leverage the open-source spirit, we’re opening up and showing our work about the entire process of how we manufacture our #IoTIntoTheWild new products at our factory. With all these, we’d love to make manufacturing as accessible as possible and keep the whole community posted on the product updates at the same time.

To stay updated on the latest #OpenManufacture news, you’re invited to follow us on Twitter or join our Discord Community.

Meanwhile, you can keep track of the latest news and information of the SenseCAP MX Helium Hotspot series through our official site.